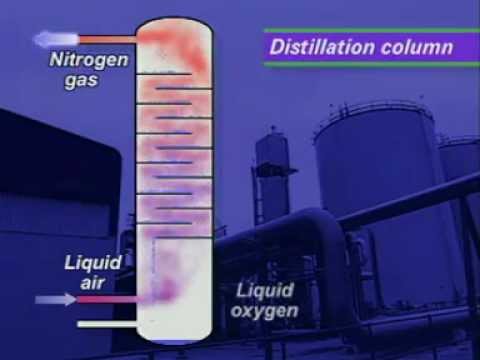

Shows how gases are extracted from air in the liquid phase, and then separated thanks to fractional distillation process in an industrial Air Separation Unit (ASU) and then compressed into gas cylinder.

Most typical gases produced by distillation: Nitrogen, Oxygen & Argon (frequently call ‘gases from air’ in opposition of gases produced from other sources, usually with a chemical process)

Uses footage examples from BOC in UK:

Related Readings & Technologies

- Cryogenic distillation: understanding the principles and operation of cryogenic distillation, which is the primary method used in air separation units to separate gases like nitrogen, oxygen, and argon.

- Pressure Swing Adsorption (PSA): exploring this technology as an alternative or complementary method to separate gases based on their adsorption properties under varying pressure conditions.

- Membrane separation technology: studying the use of membrane processes for gas separation, which can be an energy-efficient alternative for specific applications within air separation.

- Material science for cryogenics: investigating materials suitable for low-temperature operations to enhance the durability and efficiency of air separation equipment.

- Safety and environmental considerations: developing safety protocols and understanding environmental impacts associated with air separation operations, including handling cryogenic substances safely.

- Industrial applications of separated gases: understanding the various industrial applications and markets for the gases produced in air separation units, such as in steel manufacturing, chemical processing, and healthcare.

External Links on Gas Separation Techniques

International Standards

(hover the link to see our description of the content)

please include more information on the environmental impacts of these processes, such as greenhouse gas emissions

energy consumption and efficiency of different separation technologies ?

Air Separation Units, fascinating tech! But what about the energy consumption? How does it compare to other gas separation methods?