These factory tours will show all the technics and processes of probably the oldest -yet still used- tool on the earth, ie knife manufacturing. This involves steel selection, coating or treatment, machining, plastics or leatherwork, and ergonomics.

Contents

We have classified these tours from artisan/low volume to industrial high volume production, but all with excellent quality and mastering their processes and market segments.

Gough workshop

Aaron is an amateur who specialized and professionalized in his little shop and got famous in his survival knife domain. His video is very detailed in describing precisely all steps from steel selection, treatment, coating, and CNC efficiency to finishing processes, all in a one-man company and with the help of some suppliers.

Japanese Blades

Focusing on the work of steel, enjoy hand-made blades without any automation

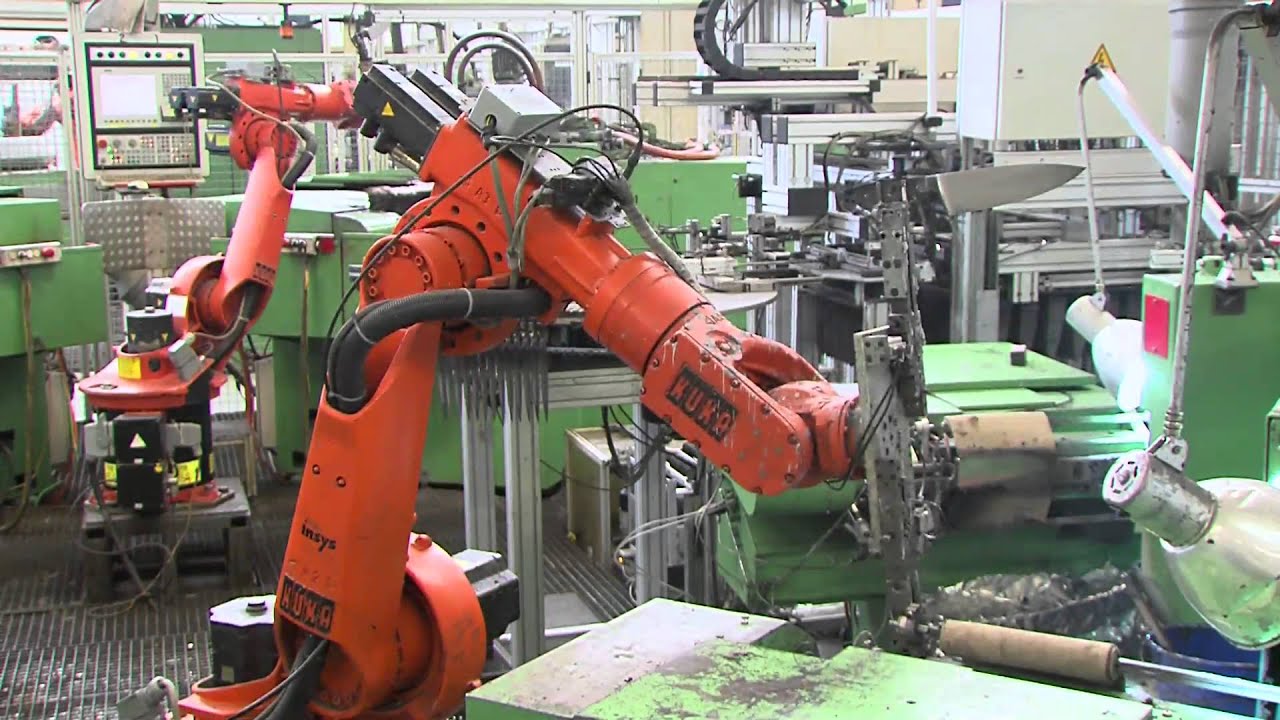

Victorinox manufacturing their Swiss Army Knife

See also other videos online by Vircorinox explaining the ideation of the product, the research, or fighting copies.

Wüsthof in Solingen

We could not finish this review without at least one factory in Solingen, one of the capitals of cutlery, and Wüsthof detailed factory video:

The 5 Typical Steps to Manufacture a Knife

Once designed, the manufacturing of the knife follows these usual steps, whether it is an artisan or a high-volume production:

- Cutting the blade: once the materials have been selected at the design phase, the steel must be cut to the desired shape and size. This is typically done

- for low volumes: manually operated bandsaw or with a CNC mill, both combined with a belt grinder or a bench grinder

- for medium volumes or large and think blades: with a laser cutter, water jet cutter, or CNC mills

- for very high volumes: as in the last videos hereabove: punched from metal rolls

- Heat treatment: after the steel has been cut, it must be heat treated to give it the desired properties. This typically includes hardening, tempering, and annealing.

- Finishing: After the knife has been treated, it goes to some fine grinders, then is sharpened, and finished. This includes polishing, buffing, and coating the steel with a protective finish.

- Assembly: the final step includes attaching the handle, bolsters, and other components and accessories.

- Quality testing and inspection, labeling, and packaging: after the knife has been assembled, it must be tested for quality and performance. This includes testing for sharpness, edge retention, and corrosion resistance.